|

|

|

|

Tower Packing>>Saddle Ring Packing Sales: Biz@jintai-group.cn

JINTAI Saddle Ring Packing

|

|

|

| Ceramic Saddle | Ceramic Super Saddle | Plastic Saddle Ring |

|

|

|

| Plastic Super Saddle | Metal Saddle Ring | |

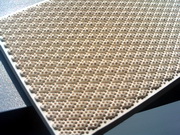

JINTAI CERAMIC SADDLE RING

JINTAI Ceramic Saddles (equivalent to Koch-Glitsch CERAMIC INTALOX SADDLES ) are between the ring shape and the shape of the saddle, and therefore maintain both their advantages, this structure is conducive to the liquid gas distribution. Ceramic saddles are most frequently used high-performance packing and exhibit advantages for most applications in comparison with other shapes. Their smooth surface imparts a high chemical resistance and provides with a high level of stability. Due to their simple form, ceramic saddles can be manufactured by continuous extrusion method and can be produced at a relatively low cost. JINTAI is the best ceramic saddles manufacturer, ceramic saddles supplier for your Choice.

Applications:

JINTAI Ceramic Saddles are widely used in Scrubbers, Drying Towers, Tail Gas Scrubbers, Impasse Towers, absorption tower, cooling tower, scrubber, regeneration tower. Also widely used as heat transfer media inRegenerative Thermal oxidizers(RTO).

Chemical composition of Ceramic Saddles:

|

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

K2O+Na2O |

Other |

|

< 80% |

17-23% |

1.0% |

0.5% |

0.5% |

2-4% |

<1% |

Physical properties of Ceramic Saddles:

|

Nominal size |

1/2" |

5/8" |

3/4" |

1" |

1.5" |

2" |

3" |

|

12mm |

16mm |

19mm |

25mm |

38mm |

50mm |

76mm |

|

|

Number per m3 |

610,000 |

269,000 |

146,000 |

59,000 |

19,680 |

8,243 |

2,400 |

|

Package density (kg/m3) |

780 |

700 |

670 |

630 |

580 |

550 |

530 |

|

Free volume (%) |

68 |

71 |

72 |

73 |

75 |

76 |

77 |

|

Surface area (m2/m3) |

647 |

535 |

350 |

254 |

180 |

120 |

91 |

|

Specific gravity (g/cm3) |

2.3 |

||||||

|

Water absorption (%) |

<0.3 |

||||||

|

Acid resistance (%) |

>99.6 |

||||||

|

Max operating temp. |

1100℃ |

||||||

|

Porosity (%) |

<1 |

||||||

|

Moh’s hardness (scale) |

>6.5 |

||||||

|

Thermal conductivity (w/m.k) |

0.9-1.0 |

||||||

|

Specific heat(j/kg℃) |

850-900 |

||||||

JINTAI CERAMIC SUPER SADDLE

JINTAI Ceramic Super saddles(equivalent to Koch-Glitsch SUPER INTALOX SADDLES) are the most frequently used high-performance packing which exhibit advantages for most applications in comparison with other packing of different shapes. Ceramic super saddles' smooth surface imparts a high chemical resistance and provides them with a high level of stability. Due to their simple form, JINTAI Ceramic Super saddles can be produced at a relatively low cost.

Applications:

JINTAI Ceramic Super saddles(equivalent to Koch-Glitsch SUPER INTALOX SADDLES) are widely used as Regenerative Thermal oxidizers, Acid Gas Scrubbers, Dryer Towers, Tail Gas Scrubbers and Impasse Towers.

Specification of ceramic super saddles:

|

Normal Size |

Approx. |

Surface Area |

Void Fraction(%) |

Dry Packing factor (m-1) |

|||

|

lb/ft3 |

Kg/m3 |

ft2/ft3 |

m2/m3 |

||||

|

1" |

25mm |

40 |

645 |

79.5 |

260 |

77 |

570 |

|

1.5" |

38mm |

37.5 |

600 |

64 |

210 |

78 |

430 |

|

2" |

50mm |

35.6 |

570 |

42.8 |

140 |

79 |

277 |

|

3" |

76mm |

36 |

580 |

32 |

105 |

77 |

206 |

Ceramic Supper Saddles Chemical Composition:

|

Composition |

Value |

Composition |

Value |

|

SiO2 |

< 80% |

CaO |

0.5% |

|

Al2O3 |

17-23% |

MgO |

0.5% |

|

SiO2+Al2O3 |

>90% |

K2O+Na2O |

2-4% |

|

Fe2O3 |

1% |

Other |

<1% |

Physical Properties:

|

Index |

Unit |

Value |

|

Porosity |

Vol % |

1 |

|

Specific heat |

KJ/Kg |

840-900 |

|

Crush strength |

N/mm2 |

390-420 |

|

Specific gravity |

g/cm3 |

2.3-2.4 |

|

Acid Resistance |

% |

>99.6 |

|

Firing temperature |

℃ |

1280 to 1320 |

|

Softening point |

℃ |

>1400 |

|

Density |

Kg/m3 |

2300-2400 |

|

Water absorption |

% |

<0.2 |

|

Thermal Expansion |

10-6mm/mm℃ |

4.7 |

|

Hardness |

Mohr Scale |

7 |

|

Comprehensive strength |

Newtons |

5600 |

|

Shock strength |

Kgf.cm/cm2 |

1.0-1.5 |

JINTAI METAL SADDLE RING

JINTAI Metal Saddle Rings or metal saddle (equivalent to Koch INTALOX SADDLES) is high performance random packing, successfully used in mass transfer towers both small and large diameter. It is frequently used in deep vacuum towers where low pressure drop is crucial and also high pressure towers where capacity significantly exceeds conventional trays, offer a 30% lower pressure drop than Pall Rings but with a lower liquid hold-up. Metal Saddles’ physical shape permits maximum randomness and minimum alignment, Advanced design gives it a high rate of liquid film surface renewal producing a high mass transfer rate, leading to a greater capacity and efficiency compared to other random packings, Large number of contact points for homogenous distribution of liquid and gas, Facilitates shorter packed bed heights.

JINTAI Metal Saddle Ring gives the best performance in terms of i.e. low-pressure drop and high efficiency. Hence JINTAI Metal Saddle Rings can be effectively used in both high pressure as well as vacuum towers. Some of its other advantages include large effective interfacial area, high mechanical strength (its monolithic construction overcomes the problem of "opening out" at ends as experienced in ring shaped packings) and low cost. JINTAI Metal Saddle Ring or metal saddle is available in various sizes, which give different combinations of efficiency and pressure drop.

Applications:

-

A versatile packing used in distillation, absorption etc.

-

Used in both deep vacuum and high pressure towers.

Material available:

Metal Saddle Ring can be fabricated from a variety of metals like Carbon steel, Stainless steel, Copper, Aluminum, Titanium, Zirconium and Special Alloys.

Specifications of JINTAI Metal Saddles:

|

Size |

Bulk Density pcs/m3 |

Surface Area m2/m3 |

Void |

Packing Factor |

|

15 |

347500 |

291.3 |

95.6 |

51 |

|

25 |

135000 |

225.8 |

96.6 |

41 |

|

40 |

50000 |

150.8 |

97.7 |

24 |

|

50 |

15000 |

100 |

98 |

18 |

|

70 |

4625 |

60 |

98.5 |

12 |

JINTAI PLASTIC SADDLE RING

JINTAI Plastic Saddle Ring (Equivalent to Koch-Glitsch INTALOX) are a versatile and economical industry standard with well-known performance characteristics. Low pressure drop, high flux, high efficiency , easy to handle.

Applications:

-

Absorption, scrubbing, and stripping services

-

Pulp and paper service, such as bleach plant absorbers

-

Versatile alternative to ceramic saddles

Performance:

Good Capacity and Low Pressure Drop

-

Higher capacity and lower pressure drop than ceramic saddles.

-

Multiple sizes provide ability to optimize capacity and efficiency based on application requirements.

Higher Liquid Hold-up and Residence Time

-

Relatively high liquid hold-up allows good absorption efficiency with slow chemical reaction.

Versatile Standard Packing

-

Lower sensitivity to liquid and vapor distribution quality allows use with conventional liquid distributors.

Specification of JINTAI Plastic Saddle Ring:

|

|

Specific surface area |

Void |

Num |

Bulk Density |

Dry packing factor F |

|

|

1" |

25*12.5*1.2mm |

288 |

0.847 |

97680 |

102 |

473 |

|

1.5" |

38*19*1.2mm |

265 |

0. 95 |

25200 |

63 |

405 |

|

2" |

50*25*1.5mm |

250 |

0.96 |

9400 |

75.2 |

332 |

|

3" |

76*38*0.6mm |

200 |

0.97 |

3700 |

59.2 |

289 |

JINTAI PLASTIC SUPER SADDLE RING

JINTAI Plastic Super Saddle Ring (Equivalent to Koch-Glitsch SUPER INTALOX) are a versatile and economical industry standard with well-known performance characteristics. Low pressure drop, high flux, high efficiency , easy to handle.

Specification of JINTAI Plastic Super Saddle Ring:

|

Size(inch/mm) |

Quantity |

Bulk Density |

Specific surface area |

Void rate |

|

|

1" |

25mm |

57500

|

91 |

199

|

0.90

|

|

1.5" |

38mm |

18000

|

72 |

178

|

0.92

|

|

2" |

50mm |

6000

|

60

|

105

|

0.93

|

|

3" |

76mm |

1500

|

48 |

89

|

0.96

|

-Ceramic Foam Filter-

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

-Tower Packing-

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

-Ceramic Honeycombs-

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

-Others-

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

-Product Navigation-

Product Photo Gallery

Product Application

CopyRight © 2005 Jiangxi Jintai Special Material LLC. All Rights Reserved

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China