|

|

|

|

|

|

|

| Alumina Ceramic Foam Filter | SiC Ceramic Foam Filter | Zirconia Ceramic Foam Filter |

|

|

||

| We can also supply good quality Ceramic Fiber Tap Out Cones for molten metal applications. | ||

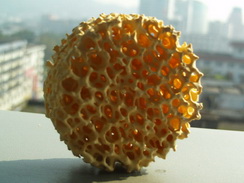

JINTAI Ceramic Foam Filter is developed as a new type molten metal filter to decrease casting flaw in recent years. Foamed ceramics have the characters of light weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, chemical corrosion resistance and high temperature stability in molten metal. With the distributing pores net structure, they are able to increase the surface areas, and absorb the sinter, the liquid metal becomes more pure, waster quality problems such as sand pore and air pore are much less. and the cast quality becomes much better.

Function & Advantages:

JINTAI Ceramic Foam Filters offer the best way to eliminate non-metallic inclusions, foreign materials that are a major source of quality problems in casting. and help you meet ever increasing demands for quality.

Get rid of the impurity, refractory scrap, solid refractory alloy, sinter, in the molten metal liquid when casting the products, get rid of turbulent flow, reduce the air cavity of castings, raise the quality of cast. So our ceramic foam filters (foamed ceramics) are widely used in the foundry industry such as casting /foundry of low carbon steel, stainless steel , iron, bronze, copper, alloy and aluminum for preventing defects caused by oxides, dross, gas, slag and other impurities.

- Eliminates turbulence in the metal stream, Smoothes out metal flow, avoiding sprays, splatter and backset. Improve fluidity, castability, machinability, yield and cost-effective.

- Remove a much greater fraction of fine particulate, Reduce rejects and rework

- Low-pressure loss.

- Provides consistent flow rate and capacity.

- Various sizes, shapes and pore sizes are available.

How Does Efficient Filtration Improve the Whole Process

JINTAI Ceramic Foam Filters offer benefits that improve molten metal handling, casting, machining, and the finished product itself.

|

Increased Fluidity |

Removal of inclusions makes the metal more fluid, resulting in easier mold fill, better cast structure, and better thin section castability. |

|

Reduced Mold and Die Wear |

Removal of inclusions and other nonmetallic debris from the melt reduces die soldering and mold-metal interaction, which degrades the mold surface and service life. |

|

Longer Tool Life |

Oxide as well as intermetallic inclusions create “hard spots” that damage tools in machining and finishing operations. Filtration reduces tool wear and increases productivity. |

|

Fewer Rejects |

Inclusions nucleate porosity, create hot tears during solidification, cause surface defects that mar appearance, and often reduce mechanical properties. In many cases, filtration cuts rejects from such causes to virtually zero. Improvements in yield to near 100% and reduced reject rates to at or near 0% are common. |

Types of Inclusions and Their Origins

Inclusions show up as alumina, silica, intermetallic sludge compounds, and other refractory and ceramic hard particles. The come from many sources: dirty charge materials, tools, ingot, oxides, foundry sand debris on returns metalworking lubricant pigments from trim, gates and risers, machined scrap castings refractory wear debris from furnaces, ladles, and other molten metal handling vessels oxidation of aluminum, magnesium, and other reactive alloy elements in the melt itself sludging in die cast alloys (precipitation of intermetallic compounds at lower temperatures) fluxing salts and/or other metallurgical additives Good furnace practice helps minimize the generation and entrapment of inclusions, but good practice alone often is not enough. You usually need effective filtration to ensure quality.

Item: JT-CFF-AL (JINTAI Alumina Ceramic Foam Filter)

JINTAI Alumina Ceramic Foam Filters are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses. JINTAI Alumina(Al2O3) Ceramic Foam Filters have excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Applications: Filters for Molten Aluminum & Alloy: (aluminium oxide) Material: Alumina (Al2O3) Working Temperture: 1200℃ Pore Size: 10,20,30,40,50,60 PPI

Item: JT-CFF-SC (JINTAI Silicon Carbide Ceramic Foam Filter)

JINTAI Silicon carbide is thermally conductive (ceramic foam filters are insulating oxide ceramics). Therefore, there is less temperature gradient between the hot and cold sides of the filter. This means less superheat is required in the hearth, and less sludging occurs because temperature can be maintained in the dip-out well. Actual temperature gradients depend on furnace design, well area, metal throughput, and filter cleanliness. Gradients less than 5℃ exist with steady metal flow - for example, during continuous dip-out, ladling, or pouring - and when oxide buildup, which is insulating, is removed periodically

Applications: Filters for Molten Iron & Alloy, nodular cast iron castings, grey iron castings and malleable castings, and for the filtration of non-ferrous metals Material: SiC (Silicon Carbide) Working Temperature: 1500℃ Pore Size: 10,20,30,40,50,60 PPI

Item: JT-CFF-ZR (JINTAI Zirconia Ceramic Foam Filter)

JINTAI Zirconia Ceramic Foam Filters -- Zirconia Ceramic Foam Filters are used for molten all types of steel like unalloyed, low alloyed, stainless and high-alloyed as well as Nickel and Cobalt-based super-alloys. With their excellent resistance to attack and corrosion from molten steel liquid, they can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Applications: Filters for Molten stainless Steel,

Alloy steel & other metal in precision molding.

Material: Zirconia (ZrO2) Working Temperature: 1720℃ Pore

Size: 10,20,30,40,50,60 PPI

Product Selection

1) Select suitable temperature filter according to kinds of alloy, the filter should not exceed temperature and damage.

2) Select suitable bore density, purification is fit in with quality of casting.

3) Select dimension of suitable filter, not increase time of moulding.

4) Reduce the second dreg.

5) Porosity: filter 80-90% when founding

Attention please:

1) The product of other specifications can also be prepared according to customers' requirement.

2) PPI (Pores Per Inch), the ppi means the number of holes per inch.

Specifications of JT CFF

Circle Shape (mm): D*H D=30~200mm H=5~20mm

Φ40*12、Φ45*15、Φ50*15、Φ55*15、Φ60*15、Φ70*20、Φ90*20、Φ150*25、Φ200*25。

Square Shape (mm): L*W*H L=40~600mm W=40~600mm H=10~50mm

Other specifications are available on your request.

-Ceramic Foam Filter-

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

-Tower Packing-

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

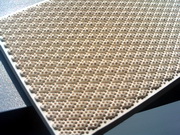

-Ceramic Honeycombs-

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

-Others-

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

-Product Navigation-

Product Photo Gallery

Product Application

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China