|

|

|

|

Tower Packing>>Ceramic Random Packing>>Ceramic Cascade Mini Ring Sales: Biz@jintai-group.cn

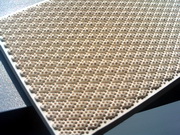

Ceramic Cascade Mini Ring

Product No: (JT-CCMR)

JINTAI Ceramic Cascade Mini Ring high-performance random packings

provide significant capacity advantages and lower pressure drop than

other random packings. These high-performance random packings have

consistently demonstrated capacity improvements of up to 15% in a

variety of applications without loss of efficiency. Superior mechanical

integrity allows processors to specify deep beds without packing

deformation. Both high performance packings are available in several

sizes and virtually any metallic material. Cascade Mini Ring random

packings are the most advanced random packing designs offered today.

Low Aspect Ratio (1/3 to 1/2 of H/D)- Key to Highest Performance for Mass Transfer. Cascade Mini Ring is the successful third-generation random packing. Since its introduction, CMR random packing has been utilized in a wide variety of distillation, absorption and stripping columns around the world. The superior performance of CMR random packing has been shown in thousands of successful installations. CMR is the random packing of choice for the majority of licensed processes. Among the many random packings available on the market, the PALL-RING has been popular for several decades. Characteristic of the PALL-RING (and most other cylindrical ring-shaped packings) is the fact that the ring height is equal to the ring diameter, i.e., the height-to-diameter ratio is equal to 1.0. The Cascade Mini Ring random packing has an aspect ratio of only 1: 3, i.e., its height is typically only 1/3 of its diameter. Seemingly minor, this change in geometry has a profound effect on the process performance of the packing. Indeed, when dumped in a tower, the "flat" CMR rings tend to orient themselves preferentially in a "near-horizontal" position, i.e., with their cylindrical axis predominantly in the direction of the vapor and liquid flow. This is exactly the opposite of the tendency of PALL-RING (and other high-aspect-ratio rings) to preferentially orient themselves on their "side" (cylindrical axis more horizontal than vertical). Performance of Cascade Mini Ring: This preferential orientation of the Cascade Mini Ring (CMR ring) brings about substantial improvements in process performance:

-

Lower pressure drop: Having its largest opening predominantly in the direction of the vapor flow allows for easy vapor passage, resulting in lower pressure drop.

-

Higher capacity: The lower pressure drop moves the operating point farther away from the critical pressure drop at which flooding occurs (typically 1-2 in. wc/ft or 10-20 mbar/m). This means additional vapor/liquid handling capability.

-

Better fouling resistance: Any solids entering the packed bed are more easily flushed through the packing matrix by the liquid.

-

Higher efficiency: This preferential orientation of the Cascade Mini Ring (CMR packing) , resulting in most of its surface being positioned vertically in the tower rather than horizontally, is also advantageous for mass transfer. It is important that as much of the available surface area as possible be effectively wetted. The underside of any horizontal surface in the packed bed is shielded from the liquid trickling down and is therefore not effectively wetted. By definition, these dry surfaces take no part in the mass transfer process and are lost.

Substituting PALL-RING with Cascade Mini Ring (CMR ring) will, therefore, result in clear capacity and pressure drop and/or efficiency gains, depending on which option the designer chooses. The high strength-to-weight ratio of the CMR packing allows the use of deep beds while minimizing the number of support plates and redistributors. CMR packing also resists compression making removal easy during turnarounds.

Cascade Mini Ring are available with the material of ceramic, metal, plastic.

Specifications of

Ceramic Cascade Mini Ring:

|

Size |

OD*H*T |

Weight kg/m3 |

Number |

Surface m2 / m3 |

Free Volume |

|

1”

(25mm) |

25*20*3 |

624 |

74000 |

250 |

75 |

|

2”(50mm) |

50*30*5 |

600 |

8980 |

150 |

78 |

|

3”(76mm) |

76*45*8 |

580 |

2800 |

108 |

86 |

You might have Interest in the following JINTAI TOWER PACKING Product:

CERAMIC RANDOM PACKING PLASTIC RANDOM PACKING

METAL RANDOM PACKING STRUCTURED PACKING

-Ceramic Foam Filter-

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

-Tower Packing-

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

-Ceramic Honeycombs-

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

-Others-

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

-Product Navigation-

Product Photo Gallery

Product Application

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China