|

|

|

|

Tower Packing>>Plastic Random Packing>>Plastic Pall Ring Sales: Biz@jintai-group.cn

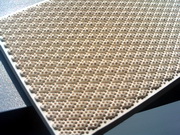

Plastic Pall Ring

Product No: (JT-PPR)

JINTAI Plastic Pall ring has an advance on the Raschig Ring, the Pall Ring has similar cylindrical dimensions but has two rows of punched out holes, with fingers or webs turned into the centre of the cylinder, which significantly increases the performance of the packing, in terms of throughput, efficiency and pressure drop.

Capacity versus Pressure Drop of JINTAI Plastic Pall ring, Most suited in low pressure drop, high capacity applications, A range of sizes of Plastic Pall rings allows the tower to operate at an optimum efficiency and throughput, Consistent ratio of free and blocked passages, independent of orientation, Large surface area : volume ratio augments the rate of liquid film surface renewal to improve mass transfer. Hold-up and Two-phase Contact, Promotes highly efficient two-phase contact and distribution; A relatively high liquid hold-up promotes high absorption efficiencies, especially in cases where the reaction rates are slow; Uninterrupted and consistent passages for gas and liquid flow.

Versatility of JINTAI Plastic Pall ring, Open, cross-linked design provides a highly efficient used of the ring’s surface area, Robust to variations in liquid and vapour distribution.

Mechanical Strength of JINTAI Plastic Pall ring, Its internal cross-structure of diametrical spars make it mechanically robust and suitable for use in deep packed beds.

Applications:

JINTAI Plastic Pall rings are widely used in Absorption, scrubbing, and stripping services, Versatile alternative to metal Pall rings, all kind of separation, constant decompress tower plants, compounding ammonia plant, decarbonization plant, separation of ethylbenzene, seperation of isooctane/ methylbenzene.

Performance:

-

Higher capacity and lower pressure drop than ceramic packing.

-

Multiple sizes provide ability to optimize capacity and efficiency

based on application requirements.

Higher Liquid Hold-up and Residence Time

-

Relatively high liquid hold-up allows good absorption efficiency

with slow chemical reaction.

Versatile Standard Packing

-

Lower sensitivity to liquid and vapor distribution quality allows

use with conventional liquid distributors.

High Mechanical Strength

-

Ring and spoke construction provides high mechanical strength, which

allows use in deep beds.

Material: PP, PE, PVC, CPVC, PVDF

|

Specification D*H*δ |

Specific surface area m2/m3 |

Void ε m3/m3 |

Num n m-3 |

Bulk Density kg/m3 |

Dry packing factor m-1 |

|

|

5/8" |

16*16*1mm |

188 |

0.91 |

180000 |

141 |

275 |

|

1" |

25*25*1.2mm |

175 |

0.90 |

53500 |

91 |

239 |

|

1.5" |

38*38*1.4mm |

115 |

0.89 |

15800 |

71 |

220 |

|

2" |

50*50*1.5mm |

93 |

0.90 |

6500 |

56 |

127 |

|

3" |

76*76*2.6mm |

73.2 |

0.92 |

1927 |

60 |

94 |

You might have Interest in the following JINTAI TOWER PACKING Product:

CERAMIC RANDOM PACKING PLASTIC RANDOM PACKING

METAL RANDOM PACKING STRUCTURED PACKING

-Ceramic Foam Filter-

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

---Tower Packing---

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

-Ceramic Honeycombs-

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

-Others-

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

-Product Navigation-

Product Photo Gallery

Product Application

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China