|

|

|

|

Tower Packing>>Metal Random Packing>>Metal Cascade Mini Ring Sales: Biz@jintai-group.cn

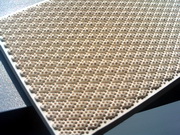

Metal Cascade Mini Ring

Product No: (JT-MCMR)

JINTAI Metal Cascade Mini Rings(Equivalent to well known Koch Glitsch CMR), JT-MCMR for short, A lower aspect ratio increases capacity and reduces pressure drop and the highly exposed internal and external surfaces give a high efficiency vehicle for liquid – gas contact with good mechanical strength.

Lower aspect ratio (H/D 1/2 to 1/3) increase capacity and reduces pressure drop; JINTAI Metal Cascade Mini Rings, preferential orientation in a packed bed with the cylindrical axis in the vertical plane, allows a free passage for gas to flow through it;

The lower pressure drop and higher throughput of JINTAI Metal Cascade Mini Rings enables a smaller column diameter and fan size to be specified in new installations, The highly exposed internal and external surfaces provide an efficient vehicle for liquid–gas contact, by multiple drip-points;

More resistant to fouling, because a combination of Metal Cascade Mini Rings' vertical alignment and open sides, allow any solids present to be flushed downwards through the packed bed.

Good Mechanical Strength, which allows JINTAI Metal Cascade Mini Rings' use in deep packed beds that have a higher hydraulic capacity.

Applications:

JINTAI Metal Cascade Mini Rings are widely used in desulfurization and decarburization system in compound ammonia plant, decompressed plant in crude oil separated plant, all kind of separation process such as separation of methanol, separation of organic acid, and used in absorb or dis-absorb tower.

Material:

Stainless steel, carbon steel, carbon steel, seeping aluminum, titanium, zirconium and special alloys.

Specification of JT-MCMR:

|

Specification |

Specific surface area |

Void |

Num |

Bulk density |

Factor |

|

|

0P |

Φ17xΦ17xH6 x 0.3 |

427 |

0.94 |

530000 |

472 |

55 |

|

1P |

Φ25xΦ22xH8 x 0.3 |

230 |

0.96 |

150000 |

270 |

40 |

|

1.5P |

Φ34xΦ29xH11 x 0.3 |

198 |

0.97 |

60910 |

201 |

29 |

|

2P |

Φ43xΦ38xH14 x 0.4 |

164 |

0.97 |

33170 |

230 |

22 |

|

2.5P |

Φ51xΦ44xH17 x 0.4 |

127 |

0.97 |

17900 |

186 |

17 |

|

3P |

Φ66xΦ57xH21 x 0.4 |

105 |

0.98 |

8800 |

139 |

14 |

|

4P |

Φ86xΦ76xH29 x 0.4 |

90 |

0.98 |

4200 |

143 |

10 |

|

5P |

Φ131xΦ118xH41 x 0.6 |

65 |

0.98 |

1480 |

136 |

7 |

You might have Interest in the following JINTAI TOWER PACKING Product:

CERAMIC RANDOM PACKING PLASTIC RANDOM PACKING

METAL RANDOM PACKING STRUCTURED PACKING

---Ceramic Foam Filter---

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

---Tower Packing---

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

---Ceramic Honeycombs---

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

---Others---

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

---Product Navigation---

Product Photo Gallery

Product Application

CopyRight © 2005 Jiangxi Jintai Special Material LLC. All Rights Reserved

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China