|

|

|

|

Tower Packing>>Structured Packing>>Ceramic Structured Packing Sales: Biz@jintai-group.cn

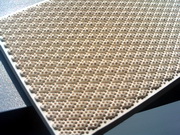

Ceramic Structured Packing

Product No: JT-CSP

Brief Introduction:

Ceramic surface can generate extremely thin film liquid flow and tortuous vapor flow passages promote mixing of liquid and vapor and, at the same time, general little pressure drop. These are reasons for JINTAI Ceramic Structured Packing have the same mass transfer efficiency as metal packing. Meanwhile, JINTAI Ceramic Structured Packings are much more resistant to corrosion and high temperature than metal packing. The surface structure of ceramic packing could promote wetting and keep liquid hold-up to a minimum.

JINTAI Ceramic Structured Packing (Ceramic Corrugated structured column packing) is constructed of corrugated sheets of ceramic. The angle of inclination of the corrugations of adjacent sheets is reversed with respect to the vertical column axis, forming mixing cells at every point where the corrugation intersect. This promotes intimate mixing and radial distribution of the liquid and gas streams. Each subsequent element is rotated about the column axis so that the sheets of one element are opposed to the sheets of the elements above and below. In passing through each element, gas and liquid are thoroughly mixed in the direction parallel to the plane of the sheets. By rotating subsequent elements, excellent mixing and spreading, both side to side and front to back are obtained over the entire cross section of the tower.

The flow characteristics developed by the structured geometrical arrangement creates high effective surface area resulting in good efficiency as compared to other mass transfer devices. (Data for our products follows: X and Y stand for the corrugation dip of 30 and 45 respectively; the Arabic numerals stand for the specific area of their series.

Advantage of JINTAI Ceramic Structured Packing:

-

The most economical range is F-factor1.5-2

-

Improve capacity by up to 50% over standard ceramic saddle Column packing

-

Excellent Resistance to Plugging

-

Improve efficiency up to 25% over standard ceramic saddle Column packing

-

Greater Heat Recovery in RTO Applications than any Random Packing

-

The corrugated sheets of ceramic are vertically oriented in the packed Column, eliminating any horizontal surfaces which create resistance to fluid flow

-

Pressure drop of each theoretical sheet is 0.3-1mbar Lower pressure drop by 60% or more over standard ceramic saddle Column packing

-

JT-CSP Column Packing geometric construction greatly reduces the channeling of both the liquid and vapor and provides for more effective contact of sulfuric acid and SO3 gas.

Application of JINTAI Ceramic Structured Packing:

-

Fining process of corrosive mixtures, which have strict requirements for pressure drop and number of theoretical sheets

-

Vacuum treatment under absolute pressure higher than1m bar

-

Fining and distillation of halogen organic compounds. Rectifying organic halide

-

Rectifying and absorbing some corrosive mixtures, which are definitely regulated in pressure drop and theoretic plate number

-

Applied in some towers that contain a large quantity of natural media used to absorb nitric acid and concentrated sulfuric acid, as well as for purifying the air in chemical plants

-

Operating in vacuum conditions at a bottom absolute pressure of 100pa

-

Used in heat exchanger and demisting, or as a catalyst carrier

Technical Parameter:

|

TYPICAL CHEMICAL ANALYSIS (wt. %) |

JT-CSP |

|

SiO2 |

≥72 |

|

Al2O3 |

≥23 |

|

Calcia, CaO |

≤1.0 |

|

MgO |

≤1.0 |

|

Fe2O3 |

≤0.5 |

|

Other |

2 |

|

TYPICAL PHYSICAL PROPERTIES |

JT-CSP |

|

Specific gravity

(g/cm3) |

2.5 |

|

Water absorption

(wt%) |

≤0.5 |

|

Acid resistance

(wt%) |

≥99.5 |

|

Loss in burn

(wt%) |

≤5.0 |

|

Max. operating Temp. (℃) |

800 |

|

Crush strength

(MPa) |

≥130 |

|

Moh’s Hardness

(Scale) |

≥7 |

Typical physical properties of JT-CSP:

|

Model. |

Specific surface

m2/m3 |

Bulk density

Kg/ m3 |

Void ratio

% |

Obl. angle |

Pressure drop mmHg/m |

Theo. plate

m-1 |

Hydraulic diameter mm |

Liquid load m3/m2h |

Max. Factor m/s

(Kg/m3)-1 |

|

JT-CSP-125Y |

125 |

320 |

90 |

450 |

1.8 |

1.8 |

28 |

0.2~100 |

3.0 |

|

JT-CSP-160Y |

160 |

370 |

85 |

450 |

2 |

2 |

15 |

0.2~100 |

2.8 |

|

JT-CSP-250Y |

250 |

420 |

80 |

450 |

2 |

2.5 |

12 |

0.2~100 |

2.6 |

|

JT-CSP-350Y |

350 |

470 |

78 |

450 |

2.5 |

2.8 |

10 |

0.2~100 |

2.5 |

|

JT-CSP-400Y |

400 |

500 |

75 |

450 |

3 |

3 |

8 |

0.2~100 |

2.0 |

|

JT-CSP-450Y |

450 |

520 |

72 |

450 |

4 |

4 |

7 |

0.2~100 |

1.8 |

|

JT-CSP-550Y |

550 |

620 |

74 |

450 |

5.5 |

5~6 |

6 |

0.18~100 |

1.4 |

|

JT-CSP-700Y |

700 |

650 |

72 |

450 |

6 |

7 |

5 |

0.15~100 |

1.3 |

|

JT-CSP-100X |

100 |

280 |

92 |

300 |

1.5 |

1 |

30 |

0.2~100 |

3.5 |

|

JT-CSP-125X |

125 |

300 |

90 |

300 |

1.8 |

1.5 |

28 |

0.2~100 |

3.2 |

|

JT-CSP-160X |

160 |

350 |

85 |

300 |

2 |

1.8 |

15 |

0.2~100 |

3.0 |

|

JT-CSP-250X |

250 |

380 |

80 |

300 |

2.5 |

2.3 |

12 |

0.2~100 |

2.8 |

|

JT-CSP-350X |

350 |

450 |

78 |

300 |

3 |

2.5 |

10 |

0.2~100 |

2.6 |

|

JT-CSP-400X |

400 |

480 |

75 |

300 |

4 |

2.8 |

8 |

0.2~100 |

2.2 |

|

JT-CSP-450X |

450 |

500 |

72 |

300 |

4.5 |

3~4 |

7 |

0.2~100 |

2.0 |

|

JT-CSP-470X |

470 |

440 |

75 |

300 |

5 |

5 |

7 |

0.2~100 |

1.8 |

|

JT-CSP-550X |

550 |

620 |

74 |

300 |

5.5 |

5~6 |

6 |

0.18~100 |

1.4 |

|

JT-CSP-700X |

700 |

650 |

72 |

300 |

6 |

7 |

5 |

0.15~100 |

1.3 |

Geometric characteristic data for JT-CSP:

|

Tower Diameter Фmm |

200 |

200~400 |

400~800 |

800~1200 |

1200~2000 |

2000~4000 |

4000~6000 |

>6000 |

|

A (mm) |

-10 |

-12 |

-15 |

-18 |

-20 |

-25 |

-28 |

-32 |

|

B (mm) |

-5 |

-6 |

-8 |

-10 |

-12 |

-15 |

-18 |

-20 |

Tolerance for JT-CSP (A is the direction of parallel the corrugate ; B is the direction of vertical the corrugate)

Typical application of Ceramic Corrugated Structure Packing:

JT-CSP-100X

Specially suitable for refinery of oil with high content of sulfur, JINTAI Ceramic Structured Packings are of excellent acid resistant performance. It is a good choice desulfurization apparatus.

JT-CSP-250X/Y

Widely used in the separations for mineral reactant solutions, rectify distillation of organic acid solutions as well absorption/recovery of sulfur acid solution.

JT-CSP-350X/Y

Widely used in the acid dehydrators to reduce reflux, increase acetic acid and lower column operation temperature. Excellent separation performance for high vacuum distillation, such as glass industry which needs high temperature resistant and corrosive resistant packing.

JT-CSP-450X/Y

Widely used in absorption, desorption, Separation of corrosive system of fine vacuum distillation requiring the theoretical plate 4-5, economic loading range: F factor 1.5-2.

JT-CSP-700 X

Specially designed for the high mass-transfer efficiency fine rectifies distillation of corrosive system which produces high quality and high purity products.

Note: every 3 to 4 meters high of this structured packing, a support grid should be installed. We also have: Ceramic Corrugated Structure Packing with holes.

You might have Interest in the following JINTAI TOWER PACKING Product:

CERAMIC RANDOM PACKING PLASTIC RANDOM PACKING

METAL RANDOM PACKING STRUCTURED PACKING

-Ceramic Foam Filter-

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

-Tower Packing-

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

-Ceramic Honeycombs-

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

-Others-

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

-Product Navigation-

Product Photo Gallery

Product Application

CopyRight © 2005 Jiangxi Jintai Special Material LLC. All Rights Reserved

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China